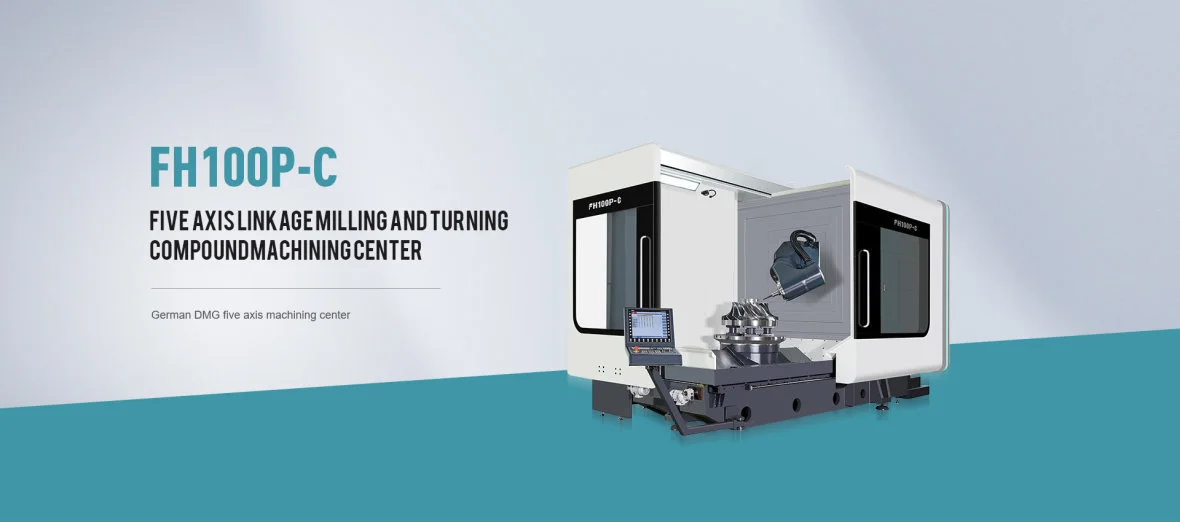

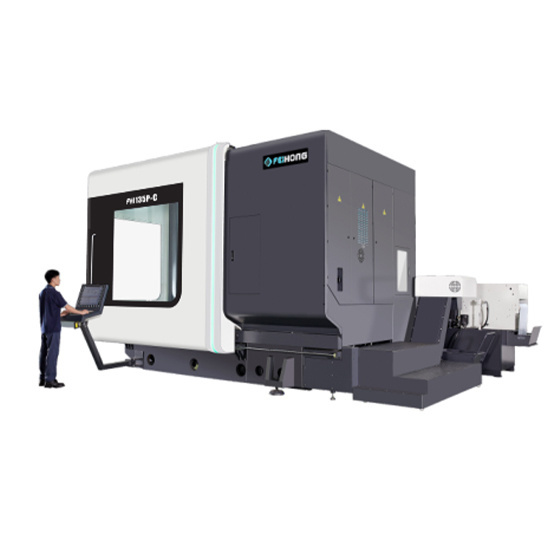

Hot model

Warp knitting machine full solution provider

ABOUTUS

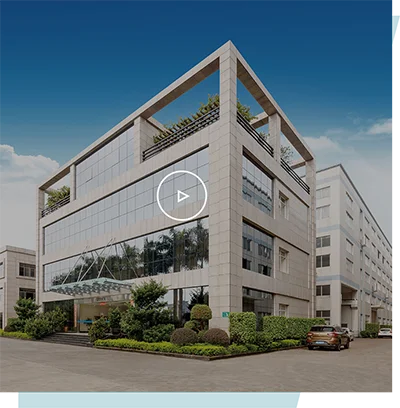

Guangzhou Feihong Intelligent Technology Co., Ltd

Guangzhou Feihong Intelligent Technology Co., Ltd. was founded in1996,covers an area of over 66,666 square meters, including over 40,000 square meters capacity of occupied buildings, at present Feihong is one of the biggest manufacture in China for Warp Knitting Machine.The company's headquarter is in the center of beautiful scenery Huadu District, Guangzhou City, near by the Guangzhou Flower City, extremely advantageous geographical location, convenience traffic, closed access to the new Guangzhou International Airport about 20 minutes by car, it is about 3km from the Haibu exit in Guangqing Highway.

The company was established in

Purchase processing center

Plant area

Annual production of various warp knitting machines

Years of experience in brand industry

Guangzhou Feihong Intelligent Technology Co., Ltd.was founded in 1996,The company has gathered a large number of scientific research elites and professional management talents in warp knitting design, research and development, production and manufacturing

01

Whole process control of product quality

The company has always adhered to the common and unremitting working principles with major manufacturers: meticulous work, strict requirements, quality control, steady development

02

Full set of technical solutions

We practice the operation of Yongji with customer satisfaction, employee willingness and business pride, and promote the competitiveness of products with innovative quality, guaranteed delivery time, affordable prices and improved productivity

03

Professional after-sales team

Provide detailed product information and various design ideas. An impartial supervision team and excellent product quality. Establish a return visit and complaint center to ensure effective handling of feedback problems

04

News

Follow Feihong and master the latest news

16

2025.07

Unlocking Precision: The Advantages of Five-Axis Machine Tools in Modern Manufacturing

Five-axis machine tools represent a significant evolution in the field of manufacturing and machining technology. Unlike traditional three-axis machines, which are limited to movements along the X, Y, and Z axes, five-axis machines add two additional rotational axes. This advanced capability allows for more complex geometries to be machined with increased accuracy and efficiency. The primary adva

15

2025.07

Why Your Manufacturing Needs a Double-Table Five-Axis Machining Center

Why Your Manufacturing Needs a Double-Table Five-Axis Machining Center Table of Contents Introduction to Five-Axis Machining Centers Benefits of Double-Table Five-Axis Machining Centers Unmatched Precision and Accuracy Enhanced Efficiency and Productivity Versatile Manufacturing Solutions Operational Enhancement

14

2025.07

Unlocking Precision: The Benefits of Cradle Five-Axis Machining Centers in Manufacturing

The cradle five-axis machining center is a revolutionary piece of equipment that has fundamentally transformed the landscape of manufacturing and machining processes. This advanced technology allows for the simultaneous manipulation of a workpiece along five different axes, enabling manufacturers to create complex geometries and intricate designs with unprecedented precision and efficiency. A fun

13

2025.07

Five-Axis Machining Centers: Revolutionizing the Manufacturing Process

Five-Axis Machining Centers: Revolutionizing the Manufacturing Process Understanding the Technology Behind Five-Axis Machining Five-axis machining centers represent a significant advancement in manufacturing technology. Unlike traditional three-axis machines, which can only move along the X, Y, and Z axes, five-axis machines offer two additional rotational axes. This capability allows for the mach

12

2025.07

Unlocking the Potential of Five-Axis Gantry Machining Centers in Precision Manufacturing

In the realm of advanced manufacturing, the five-axis gantry machining center stands out as a pivotal technology for enhancing precision and efficiency. Unlike traditional machining centers that operate on limited axes, five-axis gantry systems provide unparalleled flexibility by allowing simultaneous movement across five different axes. This capability is crucial for producing intricate geometrie

16

2025.07

Unlocking Precision: The Advantages of Five-Axis Machine Tools in Modern Manufacturing

Five-axis machine tools represent a significant evolution in the field of manufacturing and machining technology. Unlike traditional three-axis machines, which are limited to movements along the X, Y, and Z axes, five-axis machines add two additional rotational axes. This advanced capability allows for more complex geometries to be machined with increased accuracy and efficiency. The primary adva

15

2025.07

Why Your Manufacturing Needs a Double-Table Five-Axis Machining Center

Why Your Manufacturing Needs a Double-Table Five-Axis Machining Center Table of Contents Introduction to Five-Axis Machining Centers Benefits of Double-Table Five-Axis Machining Centers Unmatched Precision and Accuracy Enhanced Efficiency and Productivity Versatile Manufacturing Solutions Operational Enhancement

14

2025.07

Unlocking Precision: The Benefits of Cradle Five-Axis Machining Centers in Manufacturing

The cradle five-axis machining center is a revolutionary piece of equipment that has fundamentally transformed the landscape of manufacturing and machining processes. This advanced technology allows for the simultaneous manipulation of a workpiece along five different axes, enabling manufacturers to create complex geometries and intricate designs with unprecedented precision and efficiency. A fun

13

2025.07

Five-Axis Machining Centers: Revolutionizing the Manufacturing Process

Five-Axis Machining Centers: Revolutionizing the Manufacturing Process Understanding the Technology Behind Five-Axis Machining Five-axis machining centers represent a significant advancement in manufacturing technology. Unlike traditional three-axis machines, which can only move along the X, Y, and Z axes, five-axis machines offer two additional rotational axes. This capability allows for the mach

12

2025.07

Unlocking the Potential of Five-Axis Gantry Machining Centers in Precision Manufacturing

In the realm of advanced manufacturing, the five-axis gantry machining center stands out as a pivotal technology for enhancing precision and efficiency. Unlike traditional machining centers that operate on limited axes, five-axis gantry systems provide unparalleled flexibility by allowing simultaneous movement across five different axes. This capability is crucial for producing intricate geometrie

National Service Hotline

Guangzhou Feihong Intelligent Technology Co., Ltd.

Telephone 86 20 66606238 / 86 20 86920099 / 86 20 86920418 / 86 20 86920578

Domestic:13902405737 Manager Li

International:15013121816 Manager Wu

Fax: 86 20 86920126

Address: No. 118, Middle Section of Furong Avenue, Huadu District, Guangzhou City, Guangdong Province, China

Zip Code: 510860

E-mail:feihong@feihong-machine.com

Website:www.feihong-machine.com

Follow us

© 2022 Guangzhou Feihong Intelligent Technology Co., Ltd. SEO Tags Powered by www.300.cn City Product

WhatsApp: 15013026621

Domestic: 86-13902405737 Manager Li

International: 86-15013121816 Manager Wu

Add:fu Rong Road,Huadu District, Guangzhou City, China.

Email: feihong@feihong-machine.com

We will provide you with timely feedback